Studienfälle

Analysis of Core Thermal Management Technologies for Outdoor Advertising Machines: How to Create High-Reliability and Long-Life Outdoor LCD Advertising Machines

As an important segment of the commercial display industry, outdoor LCD advertising machines (also known as outdoor digital signages) have exposed numerous issues during the rapid expansion in previous years: vague technical thresholds leading to inconsistent product quality, homogeneous copying, vicious low-price competition, and rampant customized demands. The most critical pain point lies in the scarcity of professional thermal design talent, especially the lack of system-level cooling solutions, which directly affects the stability and lifespan of the entire machine.

Many manufacturers and even clients define "good heat dissipation" merely as "no black screen under sunlight," ignoring that thermal design is a comprehensive engineering task requiring balance among multiple indicators such as heat dissipation efficiency, dust/water protection, noise control, EMC, maintenance costs, and long-term reliability. If heat dissipation issues are "solved" by simply adding fans or reducing dust protection levels, it will inevitably lead to excessive noise, dust accumulation, accelerated brightness decay (e.g., over 30% decay within one year), and even defects such as mura, film wrinkling, and screen bursting.

As a national high-tech enterprise deeply engaged in the R&D of outdoor LCD advertising machines, Sunbao Jueneng believes that the essence of thermal design is to achieve dynamic balance between heat and the environment in extreme conditions, which requires comprehensive consideration of the following elements:

· Environmental adaptability: Temperature difference of -40℃~55℃, salt spray, dust, humidity, etc.

· Protection of optical performance: Avoid high-temperature-induced light decay and color shift in LCM modules.

· System reliability: Dust/water protection (IP55/IP65), low failure rate, long lifespan (≥50,000 hours).

· User experience: Low noise, easy maintenance, and remote temperature control management.

Forced Air Cooling (FAU)

Principle: Utilizes external cold air for heat exchange and discharges heat externally, suitable for working temperatures of -20℃~+45℃ in clean environments (e.g., residential areas, commercial districts).

Advantages: Slim size, low power consumption, cost control, IP55 protection.

Limitations: Not suitable for high-humidity, salt spray, or dusty environments; requires regular internal cleaning and is prone to dust accumulation.

Industrial Air Conditioning (ACU)

Principle: Uses an air conditioner compressor to send cold air into the cabinet for cooling electronic components, with a protection level of IP65, suitable for working temperatures of -40℃~+55℃ in harsh environments with large temperature differences, high dust, and high humidity.

Advantages: IP65 protection, good environmental adaptability.

Limitations: High power consumption, high operation costs, and thick overall product design.

Heat Exchanger (HEU)

Principle: Reduces internal temperature through heat exchange between external low-temperature air and internal high-temperature air on the metal thin surface of the heat exchange core, with a protection level of IP65, suitable for temperatures of -20℃~+40℃.

Advantages: IP56 protection, power consumption between that of air cooling and air conditioning.

Limitations: Narrow applicable temperature range and thick product design.

Low-Temperature Solutions: Heating and Insulation Design

In extremely cold regions (such as Northeast China and Russia), Sunbao Jueneng adopts an intelligent PID temperature control algorithm to dynamically adjust the heating power based on internal and external temperature differences, ensuring the normal operation of LCD screens (temperature resistance: -20℃) and electronic components. Meanwhile, an aerogel thermal insulation layer is used to reduce energy consumption, with heating efficiency increased by 25% compared to traditional solutions.

Technical Differentiation of Sunbao Jueneng

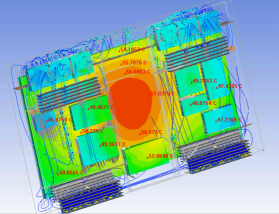

Simulation-Driven Design: Based on ANSYS Fluent thermal simulation modeling, the feasibility of solutions is verified in advance, shortening the development cycle by 30%.

Modular Structure: Supports quick adaptation to various cooling solutions such as fans, air conditioners, and heat exchangers.

Full Lifecycle Management: Built-in temperature control sensors and a remote operation and maintenance platform to monitor equipment status in real time and warn of potential risks.

The competition in outdoor digital signages will ultimately return to the core values of "high reliability, excellent display effects, and long-term stability." With full environmental adaptability from -45℃ to 55℃, 5000nit ultra-high brightness display, and modular cooling solutions, Sunbao provides global customers with full-size outdoor digital signage products ranging from 18.5 inches to 110 inches, covering various forms such as outdoor advertising machines, outdoor TVs, and mobile signages.

We not only provide standardized products but also focus on in-depth ODM/OEM customization to meet personalized display needs in different scenarios. With 16 years of technical accumulation, more than 80 patents, and mature application experience in over 100 countries and regions worldwide, Sunbao Jueneng helps partners create stable, durable, and cost-effective outdoor digital signage solutions.

Welcome to consult for customization needs and create a new future for outdoor display together!

Urheberrechte ©

@ 2026 Shenzhen Xunbao Energy Technology Co., Ltd. Alle Rechte vorbehalten

.

Seitenverzeichnis

/ Blog

/ Xml

/ Datenschutzrichtlinie

NETZWERK UNTERSTÜTZT

NETZWERK UNTERSTÜTZT